Understanding Camshaft Manufacturers in the Diesel Engine Parts Industry

Camshaft manufacturers play a pivotal role in the performance and efficiency of diesel engines. These specialized parts are crucial for the proper timing of engine valves, which directly impacts engine performance. In the ever-evolving landscape of the automotive sector, understanding the nuances of camshaft manufacturing is vital for both vehicle manufacturers and end-users alike. This article delves into the intricacies of camshaft manufacturing, the importance of quality in diesel engine parts, and how selecting reputable spare parts suppliers can enhance your engine's performance.

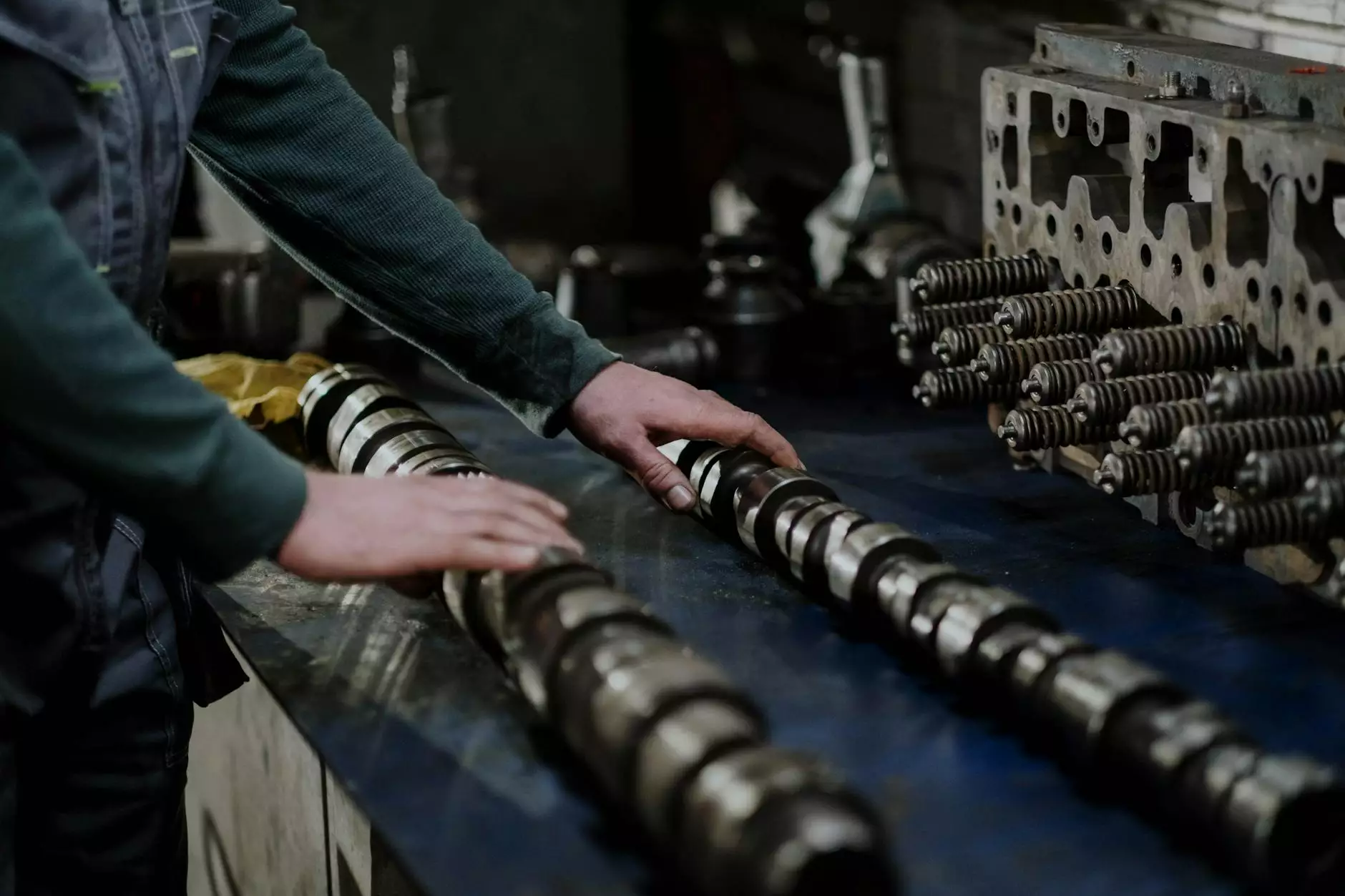

1. The Role of Camshafts in Diesel Engines

At the heart of any diesel engine lies the camshaft, a vital component that orchestrates the opening and closing of the engine's valves. This synchronization is essential for the efficient intake of air and exhaust of gases. The following points underscore the significance of camshafts:

- Timing Precision: The camshaft ensures that valves open and close at the precise moment, allowing for optimal engine performance.

- Fuel Efficiency: With a well-designed camshaft, engines can achieve better fuel combustion, leading to improved fuel efficiency.

- Power Output: The geometry of the camshaft affects how much air enters the engine, thus influencing the overall power output.

2. Types of Camshafts and Their Applications

Camshaft manufacturers produce a variety of camshafts designed for different applications. Here are some common types:

2.1 Standard Camshafts

Standard camshafts are typically used in OEM (Original Equipment Manufacturer) applications, designed to meet the manufacturer's specifications. These camshafts ensure reliability and performance, making them ideal for everyday driving.

2.2 Performance Camshafts

For those seeking enhanced performance, performance camshafts are an excellent choice. These camshafts are engineered to increase engine power and torque, making them popular among automotive enthusiasts and those who engage in motorsports.

2.3 Variable Valve Timing (VVT) Camshafts

VVT camshafts allow for dynamic adjustment of valve timing based on engine speed and load conditions. This technology optimizes engine performance and efficiency across various driving conditions.

3. The Manufacturing Process of Camshafts

The production of camshafts involves several critical steps, each of which contributes to the final product's quality and performance. Here is an overview of this intricate process:

3.1 Material Selection

High-quality camshafts are typically made from alloys that offer durability and resistance to wear and tear. Common materials include:

- Cast Iron: Known for its strength and durability, often used in standard camshafts.

- Steel: Provides greater tensile strength, often used in performance applications.

- Billet Aluminum: Lightweight and strong, commonly used in high-performance engines.

3.2 Machining

Once the material is selected, precision machining shapes the camshaft to its final form. Various techniques are employed, including:

- Turning: Removing material to form the shaft.

- Milling: Creating the cam lobes that control valve movement.

- Grinding: Ensuring precise dimensions and surface finish.

3.3 Quality Testing

Before camshafts are released to the market, they undergo rigorous quality control testing. This may include:

- Dimensional Inspection: Ensuring that the specifications match the design.

- Material Testing: Verifying the integrity of materials used.

- Functional Testing: Simulating operation to ensure performance standards are met.

4. Why Quality Matters in Camshaft Manufacturing

Choosing the right camshaft is crucial, and the quality of the camshaft can significantly affect engine performance. Here are key reasons why you should prioritize high-quality camshaft manufacturers:

- Durability: Quality camshafts are designed to withstand extreme conditions and last longer, reducing the frequency of replacements.

- Performance: Superior camshafts enhance engine response and efficiency, which translates to better overall vehicle performance.

- Safety: High-quality components are crucial for ensuring that the engine operates safely within its design parameters.

5. Selecting the Right Camshaft Manufacturer

With numerous camshaft manufacturers in the market, selecting the right one can be overwhelming. Consider the following factors when making your decision:

5.1 Reputation

Look for manufacturers with a solid reputation in the industry. Customer reviews, testimonials, and case studies can provide insights into their reliability and product quality.

5.2 Certifications

Ensuring that the manufacturer adheres to industry standards and possesses relevant certifications can be indicative of their commitment to quality. Look for ISO certification or similar qualifications.

5.3 Research and Development

Ongoing research and development efforts signal a manufacturer's dedication to innovation. Manufacturers that invest in R&D are more likely to produce advanced products that meet changing market demands.

6. The Global Landscape of Camshaft Manufacturing

The camshaft manufacturing industry is a vital component of the global automotive supply chain. Different regions exhibit varying strengths and specializations in camshaft production:

6.1 North America

In North America, manufacturers focus on both OEM and performance applications, leveraging advanced manufacturing techniques and high-quality materials.

6.2 Europe

European camshaft manufacturers are renowned for precision engineering and incorporate innovative technologies into their products, including VVT systems.

6.3 Asia

Asian manufacturers often provide cost-effective solutions and have become important players in the global market, thanks to their extensive production capabilities.

7. Future Trends in Camshaft Manufacturing

As technology advances, so too does the camshaft manufacturing industry. Some future trends to watch include:

7.1 Electrification

As the automotive industry shifts toward electrification, suppliers of camshaft manufacturers are adapting to produce components for hybrid and electric vehicles.

7.2 Increased Focus on Sustainability

With a growing emphasis on environmental responsibility, manufacturers are exploring sustainable materials and processes that minimize waste and energy consumption.

7.3 3D Printing

The adoption of 3D printing technology in camshaft production promises to revolutionize manufacturing by reducing lead times and enabling complex designs.

8. Conclusion: The Importance of Quality and Expertise

In summary, the role of camshaft manufacturers is paramount in the diesel engine parts industry. Their ability to produce high-quality, reliable camshafts directly correlates with the performance and efficiency of diesel engines. By understanding the manufacturing process, the variety of camshafts available, and the key factors in choosing a manufacturer, businesses can make informed decisions that benefit their operations. As the industry continues to evolve, staying abreast of trends and fostering relationships with trusted suppliers will be essential for success.

To enhance your engine's performance and ensure reliability, consider sourcing from reputable suppliers like client-diesel.com, known for their commitment to quality and excellence in the diesel engine parts industry.